Making

Safe Drinking Water for Life!

|

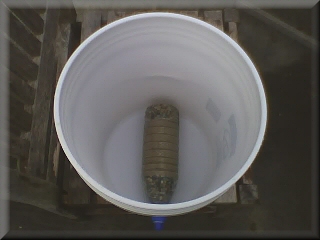

Porous Concrete Bottle Filter You may download my latest draft on 'Making Porous Concrete Bottle Filters' by clicking HERE. In March, (2011) I began in earnest to develop a recipe for porous concrete that could be set into plastic bottles and other water-tight containers to filter turbid water. I differentiate porous concrete (made from sand) that I use to purify water for people from pervious concrete (made from aggregates) that is used to make parking lots for cars. The recipes are similar, but the materials are different. Figures 1 shows a 5-gallon turbid water treatment setup using a 1-liter porous concrete bottle filter. The idea is to make an affordable filter that will remove sediment and pathogens much the way more expensive ceramic filters do. Also, I'm trying to make an efficient tool that has nearly the volume and capacity of larger biosand filters. The main advantages of porous concrete are that it is made from affordable, abundant and sustainable materials including sand, water and Portland cement that are available worldwide. Moreover, the technology is simple and easy to transfer. However, a big obstacle to using Portland cement is that it is very caustic. Concrete made from Portland cement and sand has a high ph (~13) and high alkalinity due to ingredients like sodium oxide in the cement and the formation of calcium hydroxide that is an outcome of the hydration process that forms concrete. Alkalines are being formed in concrete even after many weeks and months of cure time. The first thing I had to do was to develop a low-alkaline cement. I found straight Portland cement too caustic and raised the ph of filtered water to uncomfortable levels. Too many alkalines were being washed out with the water. The main symptoms (for me) of high ph/alkalinity is a mild sore throat that lasts for hours. On the other hand, there is evidence to suggest high ph water can kill and inhibit the growth of bacteria including e. coli. (So, this may be a blessing in disguise?) After experimenting with different proportions of fine sand, water, and an admixture of (food grade) diatomaceous earth with Portland cement, I found a low-alkaline recipe that worked. I learned that diatomaceous earth is a natural prozzolan and reduces alkalinity by reducing the amount of Portland cement needed to form the porous concrete by 30%. I further reduce alkalines in the water by adding a post-treatment filter of fine sand or (better) granulated active carbon (GAC). Finally, I found that as the filter is used and the concrete continues to cure, alkalinity decreases to palatable levels. To date, my best results come from a binary concrete-carbon filter made with GAC that is added after the concrete filter in the bottle. You make this filter with 2/3 concrete and 1/3 GAC. The carbon filter removes most of the alkalines in the concrete treated water. However, if GAC is not affordable or available, then clean fine sand will do the job - you just need to replace it more often. Even with the addition of GAC, the cost of the filter is about $2. The flow-rate of a 1-liter bottle filter inside a 5-gallon water bucket is about 1.5-gallons an hour. I expect the concrete-carbon filter to treat about 400-gallons of turbid water before being replaced by another $2 filter. Without the carbon, a 1-liter concrete-sand filter should treat 200-gallons - at a cost of about 30-cents. Figure 2 shows other kinds of filters I developed from the basic model. These include the concrete-carbon filter, bottle-to-bottle filter, personal filter, and 1/2-gallon pitcher filter. In addition to small point-of-use filters, I am developing a larger modular porous concrete pipeline section that may be added to any simple water distribution pipeline system. The idea is to filter surface water that comes directly from lakes, ponds, rivers and streams so it is fit for human and/or animal consumption. Again, you may download instructions for making Porous Concrete Bottle You can follow the 'Porous

Concrete Filter' topic on the

______________________________

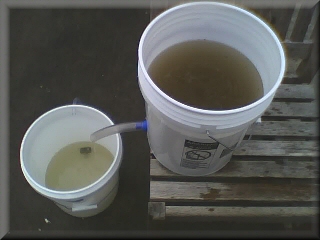

Sand Bottle Filter In January, (2011) I began development of small homemade bottle filters that I set in my ceramic gravity feed configuration. At that time, I discovered the potential of homemade bottle filters, but did not realize a stable configuration until I began testing the Doulton ceramic filter. I married the two ideas to create affordable DIY sand bottle filters. Figure 3 shows my first attempt using a recycled 1-liter PET water bottle with a 1/4-inch hole at the base that acts as an inlet. The bottle cap includes a pull-out nozzle that serves as an outlet. To make the filter, my first step was to temporarily removed the bottle cap and place it aside. Next, I cut away the plastic ring beneath the bottle cap. Next, I filled the bottle with tightly packed fine sand, sandwiched between pea gravel to make the filter. The trick is to pack the media tightly to create as solid a filter block as possible to reduce water channeling. Next, I took a 5-gallon (number 2) plastic bucket and drilled a 1-1/8-inch hole near the base even with the bottle nozzle. Then, I improvised a gasket by shaping a piece of non-toxic adhesive putty. Finally, I slipped the filter through the drilled hole and replaced the bottle cap - screwing it down to make a water-tight seal. I used a 6-inch piece of 1-inch diameter vinyl tubing to help direct the flow of water from the filter outlet. The DIY process took about 20-minutes. I found this simple filter was able to significantly improve the turbidity of dirty water for the cost of a few pennies. The turbidity is so improved that this water is ready for disinfection using SODIS or chlorine. With a flow-rate of 2-gallons per hour, this filter is a useful tool for hazardous water pre-treatment. I am still testing the tools capacity, but I estimate that 100-gallons of moderately turbid water can be pre-treated before the filter needs to be recharged with clean sand. |

Figure 1. Porous concrete bottle filter used with a 5-gallon bucket for turbid water treatment.  Figure 1b. Porous concrete bottle filter at work cleaning dirty water. (Compare the water output with Figure 3, below.)  Figure 2. Some kinds of porous concrete bottle filters being developed including binary concrete-carbon filter, bottle-to-bottle filter, personal filter, and 1/2-gallon pitcher filter.   Figure 3. Homemade sand bottle gravity filter using 1-liter PET bottle (above) , fine sand, pebbles, vinyl tubing, adhesive putty (gasket) and two 5-gallon plastic buckets. |